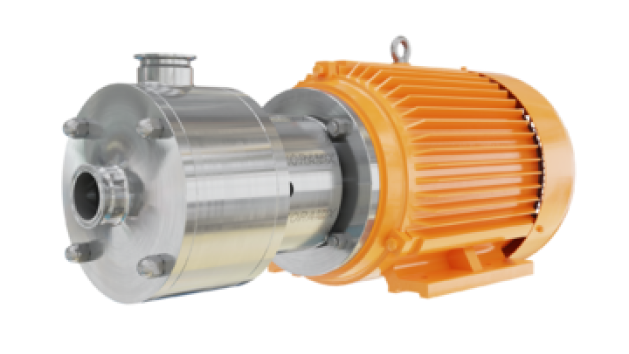

in-line mixers

In-Line mixers are supremely efficient and rapid in operation and are capable of reducing mixing times by up to 90%. The action of any In-Line mixer can be modified with the use of rapidly interchangeable workheads. This enables any machine to mix, emulsify, homogenize, solubilize, suspend, disperse and disintegrate solids.

Features:

- Aeration free

- Self-pumping

- No bypassing

- Interchangeable workheads

- Sanitary construction

- Easy maintenance

- Lower power requirevments

- Eliminates agglomerates and fish eyes

technical information

VIEW DETAILED TECHNICAL SPECIFICATIONS (PDF)-

Capacity

Self-pumping throughputs of 5 to 50,000 gallons/hr.

-

No Bypassing

Product cannot bypass the precision rotor/stator workhead.

-

Interchangeable Workheads

Single stage rotor/stator configurations as standard. For those applications that require greater shear, interchangeable multistage configurations can be used.

-

Materials of Construction

Product contact parts in 316L stainless steel. Special materials available on request.

-

Motor Specification

TEFC (Total Enclosed Fan Cooled), washdown duty and explosion proof motors are available as standard. Inverted rated, stainless steel and other motors are available as optional extras.

-

Inlet and Outlet Connections

All sanitary or flange fittings available upon request (i.e. Tri-Clamp, ASA, DIN, etc). All Silverson In-Line Mixers are designed for cleaning-in-place (CIP and SIP).